Trelleborg is a world leader in engineered polymer solutions that seal, damp and protect critical applications in demanding agricultural environments. Our agricultural innovative solutions accelerate performance for farmers in a sustainable way.

Trelleborg Wheel Systems Australia is firmly established as an industry leading supplier of wheel and tyre solutions for machinery dealers, local manufactures and tyre services. Trelleborg has invested heavily in state-of-the-art production equipment, local stock holdings and technical agricultural expertise to meet the expanding requirements of the agricultural sector Australia wide.

Trelleborg Wheel Systems is a leading global supplier of tyres and complete wheels for agricultural and forestry machines.

We have extensive knowledge of the specific applications used in agriculture and draw on this to meet the challenges you face. With a long experience of serving customers across Material Handling, Construction, Mining, Agriculture and Forestry, we have the competence and focus necessary to offer highly specialised, complete solutions to create added value for our customers.

We want to make it as easy as possible for our customers to do business with us in the way that best suits their working processes. Close cooperation and partnership is crucial for developing specialized solutions for our customers and provide optimized aftermarket service and support. Choosing Trelleborg means choosing a supplier that delivers value beyond the product.

So how has Trelleborg put delivering value into practice?

We all know that with tractor operation, we need to be able to optimise our power to the ground. Without the correct tyre set-up and tyre pressure, traction, fuel use, tyre life, and therefore cost of operation is not at its optimal level.

Incorrect tyre pressure has a significant negative impact on soil fertility as well as on tractor efficiency. The right pressure, according to machine configuration and application, boosts the performance of your tyres, increasing traction, reducing slippage and rolling resistance, with consequent higher productivity during daily operation, both in the field and on the road.

Soil compaction is one of the major enemies for your farm's productivity. A compacted soil restricts the roots growth, increases the density and reduces soil porosity. Your soil is the most important resource when growing a healthy and profitable crop.

This is why the inflation pressure of your tyres can make the difference. Trelleborg's main goal is to help you to reduce soil compaction, providing the right tool to monitor tyre pressure and adjust it where and when needed.

Why is this important?

Every time you change our tractor's configuration with different implements, change the mode of operation or even move a tractor between farms in the case of contractors of share farmers, you can reduce the effectiveness of your tractor and increase the cost of operation.

Further to this, in many applications where the loading of the tractor is cyclic, farmers need to be able to manage high to low loads within the same operation as seen in spraying and harvesting. Adopting the right tyre pressure can reduce farming variable costs by over 20 per cent. This is because this lowers fuel consumption, while increasing traction power and crop yields, protecting and enhancing the modern farming business.

What does Trelleborg offer for better farming practice?

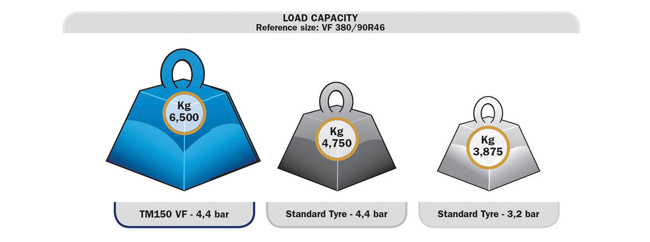

Obviously tyres! Our TM150 range is an example of a tyre that gives you more flexibility in the way that you operate your farm equipment. For example, the VF380/90R46 is able to carry up to 40 per cent more load or it can be deflated by up to 40 per cent whilst carrying the same load. The TM150 tyre is the right choice to minimise ruts and decrease soil compaction.

The advanced tread design ensures a five to eight per cent wider footprint than other standard tyres, a great benefit for increasing crop yields. The TM150 tyre features a high load capacity, which is crucial in maximising a sprayer's performance. Figure 1 shows the relative higher capability of the TM150 tyre compared to the standard series tyre.

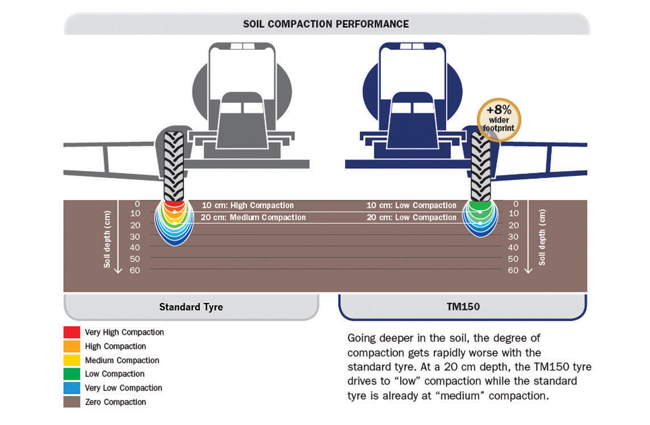

How does this relate to soil management and reducing soil compaction? The greater the displacement of weight combined with a reduction of air pressure has the effect of reducing compaction through the topsoil and the subsoil levels. Figure 2 demonstrates this point.

Having a wider footprint and carrying the same load at less pressure than a normal tyre allows significant reductions in soil compaction.

TLC & TLC Plus - manage your tyre pressure

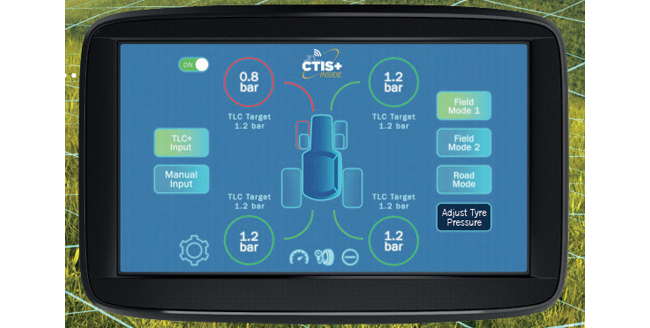

How do you calculate the correct pressures for your tyres? Our TLC app can help you to this. By capturing the key information about your equipment (tractor, ballast, and implements) the app will calculate the required pressure to optimise your tyres to the application.

You can download the app from either the Apple App Store or from Google Play. Our dedicated sales and technical team is able to assist with on site tractor weights completed via our mobile weigh scale approach.

While the standard TLC calculates the right pressure for any application, the TLC Plus checks the tyre pressure of your tractor or fleet and recommends adjustments when needed. Through the TLC Plus App, you have access to tractor data not only when next to the vehicle, but also remotely.

The innovative solution of measuring the tractor's tyre pressure in real-time, and then comparing it with the optimal target pressure suggested by the TLC Plus App, has been recognized as a big disruptor in the precision farming industry. At the Big Disruption Conference held in Amsterdam, April 11-12, Trelleborg received the ‘Disruptor Excellence Award 2019'. This award comes after the successful launch of TLC Plus, initially presented at the EIMA show in Bologna in November 2018 and then at the SIMA show in Paris in February 2019.

Need help to change your configuration?

We can help you to this. We can configure and supply new tyre and wheel packages through our factory situated in Bendigo, Victoria. Our state-of-the-art wheel building facility incorporates a high capacity CNC milling machine and an automated shot-blasting, priming and powder coating line for full in-house wheel and tyre package production capability.

Holding an extensive range of rim, centre and tyre stock under 3400 square metres of roofed racking enables a wide range of fixed and adjustable wheel option variants to be available for manufacturing without delay. With control of the entire wheel production process from start to finish, we take great pride in our workmanship and manufacturing process. It is the premium, Australian-backed tyre and wheel solution.

For more information on Trelleborg, please visit our website at www.trelleborg.com/en-au/wheels

ABOUT THIS COMPANY

Trelleborg Wheel Systems

Trelleborg Wheel Systems Australia is firmly established as an industry-leading supplier of wheel and tyre solutions for machinery dealers, local manufactures and tyre services.

HEAD OFFICE:

- 25 Darby Way, Dandenong, Vic 3175, Australia

- Phone: 397974700

- Website: www.trelleborg.com/en-au/wheels

- Email: tws.tsvsales@trelleborg.com